Water Treatment

Water Treatment

Reverse Osmosis Plant

Reverse Osmosis (RO) is a highly effective water purification technology that removes up to 99% of dissolved salts, impurities, and harmful contaminants. Using a semi-permeable membrane, RO delivers clean, safe, and great-tasting water for residential, commercial, and industrial applications. Our RO systems are trusted globally for their superior efficiency, low maintenance, and long service life — ideal for drinking water, process water, and desalination needs.

Key Benefits:

- Removes salts, metals, bacteria, and organic impurities

- Produces pure, demineralized water (permeate)

- Suitable for domestic, industrial, and municipal use

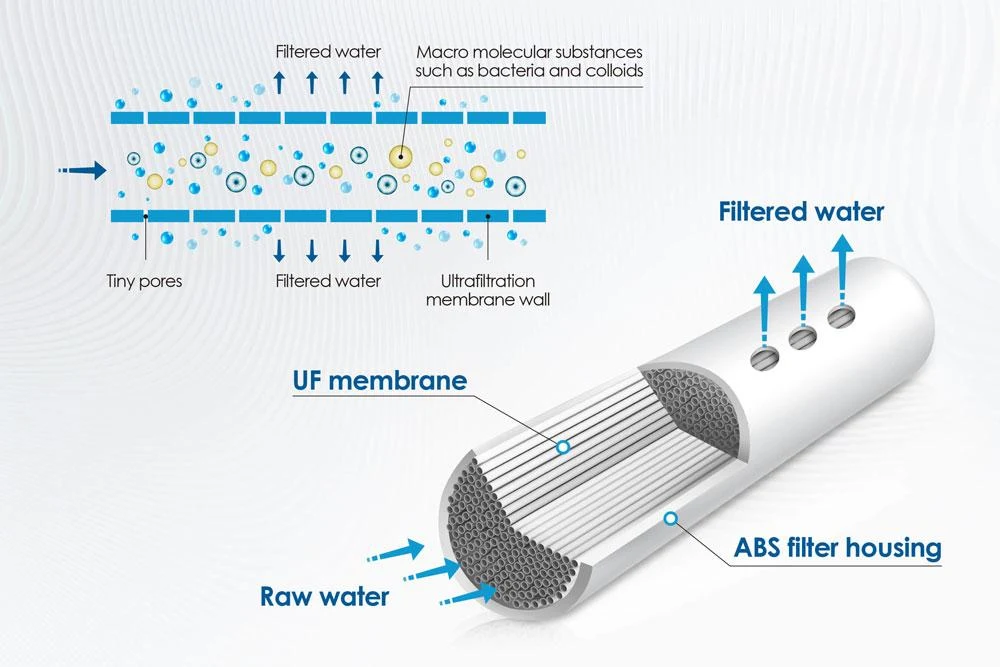

Ultra Filtration

Ultrafiltration (UF) is an advanced membrane filtration technology that removes suspended solids, bacteria, colloidal particles, and other impurities from water. Using a semi-permeable membrane, UF allows only small molecules like water to pass through while retaining larger contaminants.

Key Features:

- Removes bacteria, viruses, and suspended solids

- Ideal for pre-RO treatment and wastewater recovery

- Consistent water quality with low maintenance

- Suitable for domestic, commercial, and industrial use

Applications:

Drinking Water | Industrial Process Water | Wastewater Reuse | RO Pretreatment | Desalination Systems

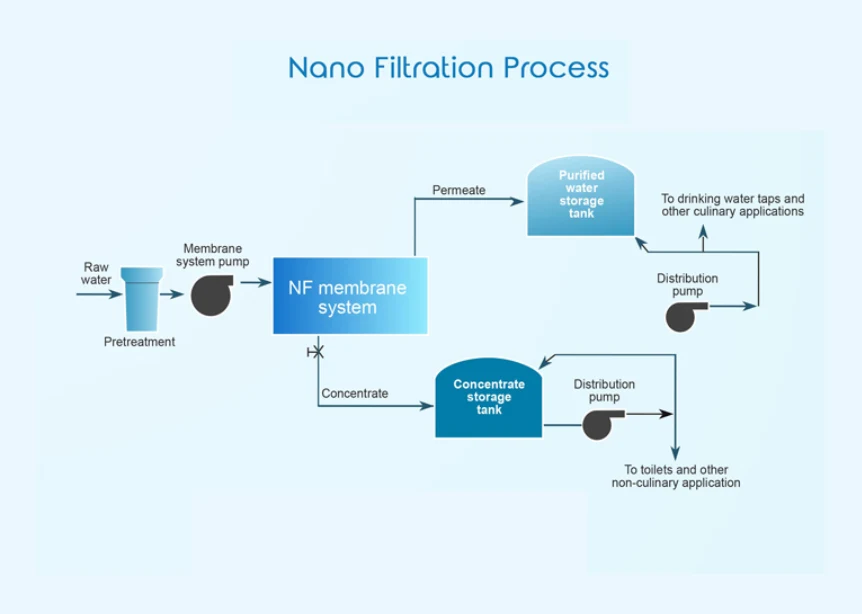

Nano Filtration

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Filtration

Activated Carbon Filtration

The activated carbon filters we manufacture are widely used to remove suspended particles, turbidity, odor, color and iron present in the raw water. These filters provide fresh water and are easy to operate.

Pressure Sand Filtration

Our assortment of pressure sand filters finds extensive application for removing turbidity, suspended particles, color, odor and iron that are present in raw water with minimum pressure drop.

Chemical Dosing Systems

We fabricate optimum quality chemical dosing systems that offer the correct quantity of dosing chemical in the stream. These chemical dosing systems are used in different chemicals such as acids, alkali, chlorine, anti-scalant, alum, polyelectrolyte, and others. Moreover, we can also customize our range as specified by the clients.

Disinfection

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book..

Softening Systems

Water as such in nature after percolating through earth will naturally dissolves minerals and becomes saline depends on the earth strata. This includes hardness causing salts such as Calcium and Magnesium and other natural minerals like sodium, potassium of positively charged ions which will be entangled with negatively charged ions like chlorides, sulphates, fluorides, Nitrates, phosphates etc. in nature. The hard water contains more hardness which consumes more detergents while washing, bathing and even in floor cleaning.We provide both salt and resin based softeners, which will remove hardness and give soft water for domestic usage as well as for industrial use

De-Mineralization

Our demineralization plant performs efficiently in purifying and removing a variety of impurities from water. Equipped with advanced filters, our demineralization plant helps in faster removal of odors, colors, and related harmful chemical contaminants. Water treatment through a demineralized water system makes water safe for drinking by using different types of ion-exchange resins